-

We have supplied 25 companies with high-precision core components, and the precision range of KESO is good at is 0.005-0.02mm, whether it is a series of aluminum alloy, engineering plastics, high temperature resistant materials and high hardness materials have a complete set of solutions. We have a lot of processing experience in the fields of shaped structural parts, robot parts, high-precision shafts, optical products, high-end analysis and inspection equipment

-

The positioning fixture is developed for the special-shaped complex workpiece, the repeated positioning accuracy can reach 0.005mm, and the whole workshop can be interchangeable. Once clamping can be processed in full sequence. Solve the error caused by repeated clamping, and can effectively control the shape position and dimensional tolerance

-

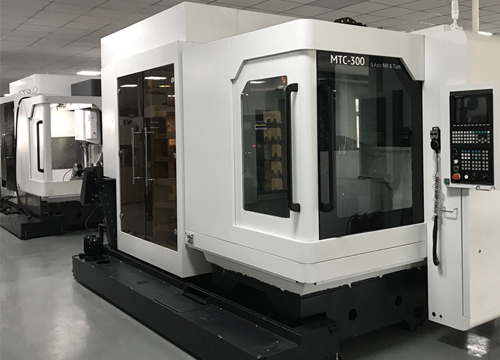

Independently developed five-axis grinding center, automatic loading, standing 200 tool library, support abnormal automatic scheduling, suitable for mass material manufacturing. It is suitable for the processing of high hardness, high precision and heterosexual complex materials, and can process 0.002mm precision and HRC62 hardness materials

-

With the introduction of German GOM and Zeiss automatic measurement technology, the three-dimensional model is reversed and compared, and a complete application scheme is developed for the second time, with efficient measurement scenarios. From machining to measurement, the precision of 0.005mm can be switched, and the technology is applied to the rapid measurement of the size in the manufacturing process.

Wechat

Wechat KESO Tik Tok

KESO Tik TokE-mail : zhanghl@kesochina.com

Craft Centre: 5th Floor, South Building, Beinong Science and Technology Complex, Beiqing Road, Changping District, Beijing

Address: Building 106, Jingxi Incubation Base, Huailai County, Zhangjiakou